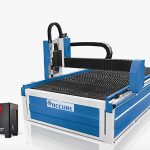

Características do fabricante da máquina de corte a plasma cnc 63 / 100A

1. A máquina cortadora de plasma CNC 63 / 100A adota um design estrutural leve, a estrutura tem boa rigidez, peso leve e pequena inércia de movimento.

2. Estrutura tipo-guarda. O eixo Y adota motor duplo síncrono e driver, e os eixos X, Y, Z adotam guias lineares, transmissão estável e alta precisão operacional.

3. Palavra publicitária tridimensional de LED principalmente cortada, placas de metal com caracteres de ranhura e rodapés, e a precisão de corte atinge um índice excelente

4. Pequenos furos de corte, organização e fenômeno de nenhum resíduo, evita o processo de modelagem na segunda vez.

Velocidade de corte 5.Fast, elevada precisão e baixo custo. Sistema CNC com configuração alta, greve de arco automático e desempenho estável, com acima de 99% taxa de sucesso de greve de arco.

6.Support para arquivos de caminho de código G padrão que são gerados por softwares como Artcut, Artcam, Type3. Os arquivos no formato DXF gerados por softwares como o AUTOCAD também podem ser lidos através da transformação de software. O sistema de controle adota o disco de U para trocar arquivos de processamento, a operação é conveniente e rápida.

7. Máquina de corte CNC para plasma Huayuan 63 / 100A fonte de alimentação e tocha acesa são equipadas com marcas nacionais famosas. e eles são fabricados por fábricas com tecnologia de patentes nacionais multi-termo

Parâmetro técnico

Área de trabalho: 1300 * 2500mm

Garantia: 12 meses

Velocidade de corte: 8000mm / Min

Sistema de controle: Iniciar sistema de controle

Materiais de processamento: ferro, alumínio, aço inoxidável

Potência do plasma: 65-200A

Mesa de trabalho: Mesa de trabalho de lâmina

Espessura de corte: 0,1 mm-30 mm

Tensão de entrada: 380V trifásico

Trilho de guia: Taiwan Hiwin Liner Guide

Pacote de Transporte: Caixa de Madeira Compensada

Especificação: Padrão CE

Código HS: 8456100090

| Parâmetro do Modelo | máquina de corte plasma cnc | ||

| Modelo | DEK-1325P | DEK-1530P | DEK-2040P |

| Tamanho de trabalho | 1300 * 2500 mm | 1500 * 3000 mm | 2000 * 4000 mm |

| Três eixos Repete a precisão do posicionamento | ± 0,05 mm | ||

| Precisão do processo | ± 0,35 mm | ||

| Sistema de transmissão | X, Y Taiwan Hiwin de alta precisão, folga zero guia linear aumentada + rack Z o controle de tensão do arco | ||

| Máx. velocidade de corte | 15000mm / min | ||

| Tensão de trabalho | AC380 / 50HZ | ||

| Sistema de controle | Sistema de corte a plasma Beijing START Dispositivo padrão de alta sensibilidade de tensão de arco | ||

| Suporte de software | FASTCAM, AutoCAD, | ||

| Formato de instrução | Código G | ||

| Sistema de direção | Motor de passo (servo motor Taiwan AC opcional) | ||

Potência do plasma | Huayuan doméstico 63A-200A Importado US Powermax 63A-200A | ||

| Capacidade de corte de energia | Huayuan doméstico 0,5-30 mm US Powermax series 0,5-50mm | ||

| 63A, espessura de corte de 0,3-8 mm 100A, espessura de corte de 0,3-18 mm 160A, espessura de corte de 0,3-25 mm 200A, espessura de corte de 0,3-35 mm | |||

| Pressão no trabalho | 0,65-0,8Mpa | ||

Aplicações

As máquinas cortadoras de plasma CNC são amplamente utilizadas para cortar aço inoxidável, aço carbono, aço estrutural, alumínio, ferro, chapa galvanizada, placa de titânio, placa MS para sinais, componentes arquitetônicos, unidades de fabricação, etc.

Indústria de aplicação: Indústria de chapas, utensílios de cozinha, componentes, decoração.

Perguntas frequentes

1.Como posso saber se esta máquina é adequada para mim?

Antes de fazer o pedido, forneceremos todos os detalhes da máquina para sua referência, ou você pode nos dizer sua peça de trabalho, nosso técnico irá recomendar a máquina mais adequada para você. Além disso, podemos fazer uma amostra com antecedência para você verificar se o seu desenho é fornecido.

2. se houver problemas na máquina, como você fornece o serviço?

Em primeiro lugar, começaremos imediatamente a dar-lhe a resolução do problema, se for necessário pessoal no passado para ajudar a resolver, o nosso pessoal de pós-venda da máquina de escultura em pedra chegará dentro de 3 dias úteis (de acordo com a distância).

3. Como você faz o que ferramentas de escultura em pedra, como obter o suficiente.?

Gravação CNC precisa de ferramentas de corte, geralmente não fornecemos diretamente, iremos chamá-lo de um parceiro, solicitando ferramenta diretamente para você. Tentamos não fazer, a fim de reduzir mal-entendidos

4.Se a máquina tiver problemas, o que você pode fazer para ajudar?

As peças gratuitas serão enviadas para você dentro do tempo de garantia e há suporte técnico 24 horas por dia, 7 dias por semana, por correio e telefone. Nossa equipe de pós-venda pode ir à sua oficina se o problema ainda não puder ser resolvido.

5. quanto tempo leva para usinar um relevo de metros quadrados?

Eficiência de trabalho da máquina de gravura e a complexidade do projeto, profundidade de processamento, processamento de material e facilidade. Estimativas de tempo tão ruins, gravadas em nossa página de amostra da empresa com dados de amostragem prática relacionados para sua referência.

Treinamento para o cliente:

1). Forneceremos o manual de operação da máquina na versão em inglês para: instalação e operação, incluindo introdução para a composição do equipamento, princípio de funcionamento do equipamento, conhecimento comum de computador, princípio de controle de dispositivos elétricos, medidas de manutenção diária do equipamento. Demonstração pessoal para instalação e ajuste de equipamentos, operação de equipamentos, programação de computador.

2). O usuário pode enviar representantes à nossa fábrica por 2-3 dias para treinamento. Somos responsáveis por treiná-los gratuitamente. Enquanto todas as despesas, incluindo despesas de viagem e acomodação, serão pagas pelo usuário.